|

General Description

Macqu system was developed to cope with demands for higher levels of automation and data acquisition. It can be used to apply hierarchical and distributed control strategies that integrate estimation, prediction, adaptation, learning, fault detection and fault tolerance.

Basically Macqu is a SCADA system, which incorporates its own special PLC (Programmable Logic Controller) with a class of generic control functions and signal processing math library, and the flexibility to support a variety of I/O signals (sensors-actuators etc.). With these tools Macqu can control and manage complex process operations properly. It also includes an embedded fuzzy inference system for high-level decision-making, coordination and management of hierarchical systems. Special built-in functions for event driven control loop activation, support basic and complicated applications for greenhouses and fisheries. With recent additions for IP connectivity, operations modelling, an optimiser and remote camera support, the system has become a virtual laboratory system for training but also for remote management and control.

Functional objects

Virtual variables (VV)

Output drivers (OD)

On-line optimization tool

Presentation objects

Data base

Virtual control loops

KBS-Tasks/subtasks

Multiple Hardware support

Internet Connectivity

Remotely controlled Internet camera

Description of a case management problem (greenhouse management)

One of the main advantages of Macqu systems is that it was build as an “open” automation and management system. The word ‘open’ denotes the flexibility of the system to adapt to any control or management application.

The main innovative features implemented to provide a flexible system are:

Functional objects

Object oriented design not only on the programming style but also on the “user_functionality”. A complete set of “prime functions”, needed at the different signal processing stages, [input stage]-[processing stage]-[output stage], was identified and each “prime function” was designed as independent object. These objects can be specified and chained to provide a “custom” higher-level function, i.e. management of supplementary lights.

Virtual variables (VV)

The “user”, starting with the hardware input variables, can institute, during execution, new variables as functions of other variables, i.e. the measurements. Such a nesting has no limit (except physical memory). A rich set of function templates (library) has been designed-in, from which the user can select his signal processing building blocks. Common Mathematical functions (e.g. Polynomials, sin, exp, integral, derivative, etc), adjustable Time-Integrated-Variables, digital delay lines with taps, first and second order system models, multi_in_one_out, thresholds/decisions, time_switches and multi-point day_clocks, hard and soft events, are some of such VVs which can be specified and used as input or control for other functions. It is impressive that almost all blocks contained in the Simulink program of Matlab can be generated from the Macqu VV library. Set Point Generators, load dividers, adaptive schedulers are some additional tools provided by Macqu.

Output drivers (OD)

Various type of equipment is used, depending on the technological status and the process involved. Output functions available are: bipolar or unipolar ON/OFF with hysteresis, PWM and Pulse Frequency Modulation (PFM). Analog control commands, supplied by a control loop, can be tied with a selectable output driver, to conform to the type of actuator used.

On-line optimization tool

The system is also equipped with an on-line process optimization tool, which was built based on a modified search algorithm with accelerated learning. Each process, when entered under the optimizing monitor, must be performance driven (see Fig. 1).

|

Fig. 1. The optimizer can be assigned to any object.

The system conducts real experiments on the site and uses a modified descent method to maximize performance. This tool has been used to tune parameters of humidity control in plant propagation chambers and also in irrigation scheduling applications.

Presentation objects

A rich library of presentation tools was implemented to allow system customization on the site, to create an attractive and intuitive desktop. The screen can be organized to tile or cascade a number of windows, each including a real time presentation of the virtual variables (see fig 2). The real time graphics include scroll graphs, table type data viewer, dynamic bars (i.e. can imitate a tank level), analog meters or a mimic diagram with animation from the work place.

|

|

|

| Greenhouse | Pisciculture | Hydroponics |

Fig. 2 A typical presentation window containing various Presentation objects.

Data base

The Data base, based on the Access engine, can store data which can be later retrieved and visualized by the user. This is very useful for long time monitoring and data collection. Data exporting is also facilitated.

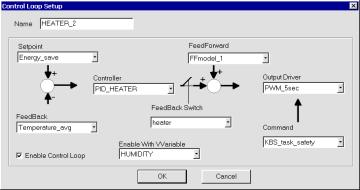

Virtual control loops

Almost any control philosophy can be implemented using a well-defined chain of building blocks and smart virtual variables. Non-linear PIDs of the general form depicted in Fig. 3, starting from a VV reference and leading to configurable output functions and functional enable/disable switches are the tools to build control loops. These loops may also be nested or cascaded. Virtual variables can implement models used for adaptive set-point reference (to optimize greenhouse performance) or for a feed-forward action (to improve loop performance) or other building blocks to enhance loop performance (e.g. a Smith predictor).

|

Fig. 3. Macqu Virtual control loop

KBS-Tasks/subtasks

Higher level management can be implemented using a Fuzzy Logic, rule based expert system, native of Macqu. This system provides input, output and rule editor on line. The outputs can directly affect the greenhouse equipment or may influence control loops

Multiple Hardware support

Almost all on-line sensors and actuators found in the market can be supported by Macqu system with minimum or no modifications. In particular all sensors with voltage, current or frequency outputs can be combined with Macqu. Moreover Macqu can drive actuators, using its supporting output drivers, with digital (on-off, etc) or analog (analog voltage or current, 4-20 mA current etc.) techniques.

Internet Connectivity

Macqu internet-access is based on a Client/Server computer configuration as it can be seen in Fig. 4. The user is located at the client side and can use any computer with Internet access. The server is a PC located near the greenhouse. The server sends to the client all requested measurements and transfers all set-up commands transmitted by the client to the Macqu controllers. The Macqu controllers are responsible for executing these commands and send to the server the new measurements and images.

|

Figure 4. Remote control case: The PC station is connected to the controllers via Internet.

This configuration has the advantage that the controller handles all control locally. In this way, problems caused by the network quality of service (QoS) are avoided. During a remote access of the greenhouse the control logic runs in the controller but all system variables are available in the remote station for monitoring, using a rich set of presentation graphics. Thus, the whole operation is transparent to the user, the controls run in real time locally in the greenhouse and the results are available remotely, at the connection speed, without affecting the real mode operation.

Remotely controlled Internet camera

Further support is available for a camera connected to a Macqu controller to send images of greenhouse interior to the remote PC through Internet. The channel throughput is divided by the user between monitoring data and camera frames.

Camera use is for:

Visual Monitoring the Greenhouse (GH)

Managerial reasons

Inspection and Diagnosis of machinery

As a Camera Sensor with good zoom to detect diseases, to measure growth and to become an advanced sensor in the future

Electronic commerce between the grower and the consumer, advertising the product in the GH

A Macqu system can be used for both commercial and research applications. All the possible connections of the system are presented in figure 5.

|

Fig 5. Macqu communications for commercial applications experimentation and research

The user of Macqu, depending on the application can be connected either to a physical controller, which is responsible for the greenhouse management, or a simulated controller which is running locally on the computer where Macqu program is installed. The connection to the physical controller can be achieved either directly by a cable connection using RS232 protocol or through Internet using TCP-IP protocol. As it was previously described all the measurements, management, decision and control actions are performed locally by the controller, hence, in the case where the connection is through Internet, the performance is not affected by the network quality of service.

The simulated controller can be used in combination with the greenhouse models supported by Macqu to simulate and test new control strategies before they are applied to the physical system. The user can define the external conditions of the simulated system (e.g. weather conditions, etc) using an external text file.

The Virtual models, incorporated in Macqu or designed using virtual variables, can be used either to simulate the process or by the controller to predict the performance of the process.

Description of a case management problem (greenhouse management)

To demonstrate the use of Macqu to an integrated management problem, here we describe an application to the greenhouse management.

The greenhouse (GH) production process must be viewed and managed at different time scales. Within Macqu the overall process is organized as depicted in fig. 6. This scheme provides a platform for an open system to implement all modern control techniques and plant management strategies. At the inner loop (fig. 6) GH physics, disturbance loads, plants' macro-environment as well as equipment variants, with their mode of operation and control methods (ON/OFF, PDM, disturbance compensated PID, FF/FBC etc) are met by using virtual variables and control loops (see fig. 3).

|

Fig. 6: Multiscale management and control of greenhouses

At the medium term of sensing and reacting loop, micro-environmental issues, plant's biological responses (water/heat/cold stresses, time gradients and risky conditions, etc) and stage of growth are taken into account. Macqu has considered the possibility of connecting advanced sensors for the real practice. At this stage, this concept is only met by expert models (virtual variables can create models i.e. TIVs, other integrals etc). This loop responds to processes in the time scale of hours to weeks and are the means to generate optimal diurnal set-point trajectories.

At the outer loop, crop cycle planning is concerned with user goals, specific plant variety requirements, site weather data and energy availability as well as grower's experience for the management of his crop and greenhouse. These are long term responses and regard the accumulated experience of the grower or the scientific data (as research results or growth models etc). Experiments conducted by scientists over the years and concluded results enhance the application domain knowledge needed to close this long-term feedback loop. Scientific or grower’s data provide the blue prints for managing the greenhouses. These data are better utilized if fed to a scheme setting the constraints for the medium term loops. This concept can be implemented in MACQU only through seasonal user’s interventions or in the rule base by expert rules or rules communicating with a production model.