|

|

|

|

|

|

Productivity Model 3-25 m3/h |

Show-Room model 3-10 m3/h |

Research Operation model 0-3 m3/h |

||

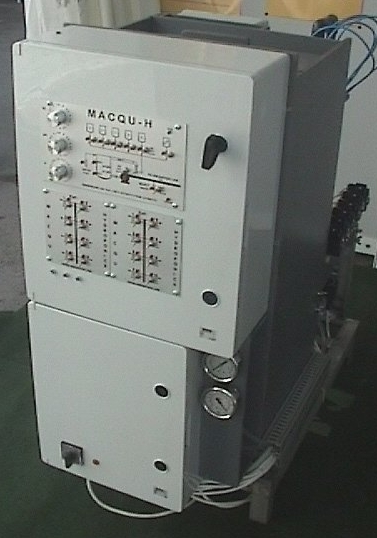

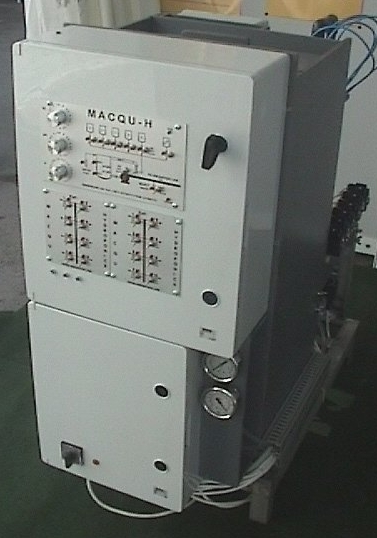

MACQU HYDROPONICS MACHINE

(MACQU-H)

|

|

|

|

|

|

Productivity Model 3-25 m3/h |

Show-Room model 3-10 m3/h |

Research Operation model 0-3 m3/h |

||

CONTROL AND MANAGEMENT SYSTEM

Hydroponics on substrates

NFT

Fertigation on soil

Market demand for higher quality products is increasing while the profit margins are declining. Modern technologies and new cultivation methods make it possible to reduce cost and increase production and quality. To have such results, more accurate control and management of cultivation inputs are necessary to maximize the effectiveness of all available production means. On the other hand some resources are getting scarce (i.e. good quality water) while environmental restrictions are becoming constraints more difficult to meet. An efficient management using smart machines can increase the usability of low quality water and reduce the environmental and profit leaks.

N. Sigrimis, AUA workshop 21-10-98

MACQU-H is a Hydroponics machine, developed within MACQU project of EU-DGVI. It is of simple and compact construction, has a minimum of moving parts, for least maintenance, and all materials used are corrosive-resistant to acid fluids. A special multi-venturi (patented) guarantees precise dosing of stack fluids with a total solution tolerance of 3% or better. It is using a powerful micro-controller, which executes the programs continuously and autonomously with zero downtimes. Once configured on the site the user can alter his management parameters through the office PC program or using knobs on the machine. All sensors (low/high pressure, temperature, EC, pH) have duals for safe operation and warnings. All operating elements (pump, dosing valves, irrigation valves etc) have dedicated switches on mimic diagrams for user intervention and troubleshooting. Powerful configurable displays on the office PC provide a user customizable monitor. It communicates with MACQU-C, the Climate computer, to read climatic conditions and adapt irrigation and nutrient solution programs for more efficient, weather adaptive, management. The solution supply is pressure regulated, rate adaptive with a high dynamic range to operate highly different irrigation lines while assuring standard performance /miniscule variation on EC and pH/. Its versatility and Internet connectivity makes it also excellent as research apparatus.

GROWER’S BENEFITS

Water and Fertilizer economy

High product quality and high yield

Maximal economic result

MACQU HYDROPONIC CHARACTERISTICS

Operates on open, and closed irrigation systems

IRRIGATION MANAGEMENT

The irrigation programs may be scheduled on:

Specified Time Schedulers (Weeklong programming with one second resolution).

Substrate or soil available moisture, with safety limits (sensor based - soil moisture, tensiometers etc).

Using a transpiration model.

Specified drain percentage with use of self-adaptive transpiration model and drain meter.

PLANT NUTRITION CONTROL

The solution concentration (EC) can adapt to weather conditions to match water/nutrient demand.

Nutrients’ ratio can adapt to light intensity and temperature to supply the exact needs of plants for best quality products and vegetative growth control.

Measure drain EC and pH to compensate in solution preparation and control of flashing.

REGULATION ACCURACY

The accuracy of total solution concentration is better than 2%, due to the multi-venturi approach.

EC and pH is absolutely steady, at the start and during the whole irrigation period, with a proprietary control program.

All parts in contact with the highly corrosive stock solutions are of PVC material for long life and precise functioning.

PROGRAM CAPABILITIES

Upto 10 different, user defined, hydroponic programs.

Each program can operate upto 10 stock solutions. Mixing rations of each stack are user defined for each program. That is even with 3 tanks the user can implement many nutrition recipes i.e. 5-3-2, 5-3-3, 1-1-0, 3-0-2 etc

Unlimited daily irrigation schedules.

Selectable automatic pure water/plus acid/ line-purge at the end of each irrigation.

Weather adaptive irrigation frequency schedules.

Self-Adaptive transpiration model driven irrigation schedules for minimum consumption of water and nutrients.

It accepts very narrow operation and alarm limits (i.e. if a hose breaks or a tank is empty it holds irrigation and sends alarm).

Selectable purging of mixing tank at the start of each irrigation.

HARDWARE TECHNICAL CHARACTERISTICS

Upto 10 stack solutions plus acid/base can be used without additional hardware.

Dual sensors on EC and pH for safety and auto-testing.

It can operate in closed loop irrigation or NFT for minimum environmental effluents.

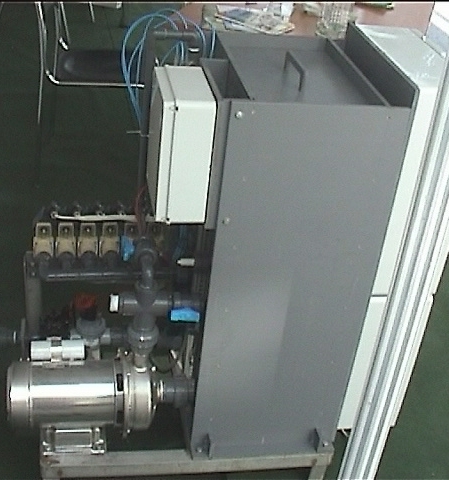

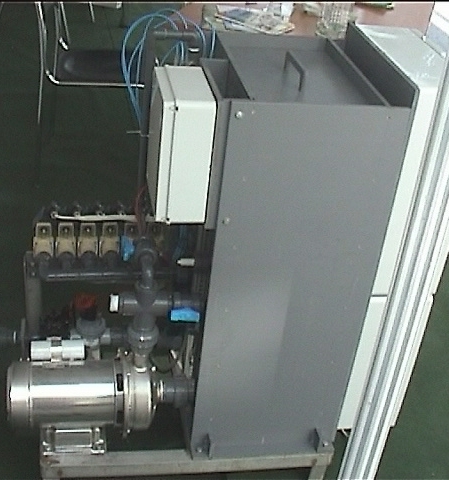

Embedded PVC mixing tank of 40 LT, with auto analog feed and dual upper/lower limits. PVC tubing and dosing valves.

Embedded stainless irrigation pump with three different capacity models (2-5, 4-10, 8-20, m3/h & discharge head regulated at 3-4bars). Requires water feed at 1-5Atm.

Operates upto 56 irrigation valves, in modules of 8.

ON-OFF-AUTO switches on all live parts (pumps, valves etc) with LED indicator.

Programmable alarms and warnings.

Operating temperature range 5-40OC.